For high-temperature technology, high-vacuum technology, chemistry and reactor technology

Diamond gaskets have proven excellent in high temperature engineering, high vacuum engineering, chemical and petrochemical industries as well as in nuclear technology. Diamond gaskets are metallic gaskets. Like all metal gaskets, they require high sealing surface pressures. As it is the “tip” of the diamond that bears pressure first of all, the necessary forces are much lower compared to other metal gaskets. So that the diamond gasket does not damage the flanges, the gasket should have a lower hardness than the flange material. In stainless steel flanges the diamond gasket is made of the same material. Gasket and flange have roughly the same hardness. Diamond gaskets are also used with an inner or outer centring ring.

Dimensions: Specified by client

Materials: 1.0333, 1.4571, 2.0090, 3.0255

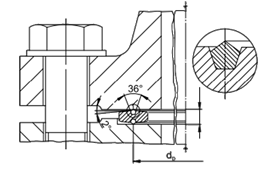

A further development of the diamond gasket is the H-gasket. A H-gasket is a fully metal gasket consisting of a chamber ring and two and/or four sealing rings. The ring, which is H-shaped in cross-section, chambered and load-bearing, should preferably be made from a hard and elastic material. The end faces of the chamber ring should be sloped by 2° towards the flange surfaces, so that the security of the seal diameter dG is retained even if the flange is tilted. Both sealing rings are pentagonal in cross-section and are made of an easily-deformable, plastic metal. At very high pressures,two or three of the same kind of sealing ring can be arranged concentrically. The surface quality of the flange should be Rz< 16 µm. In order to meet all the requirements of day-to-day use we have extended the sealing ring to three profile widths, so that, in conjunction with the double-layering technique, there are effective sealing widths of 3.2; 4 and 4.85 mm available.

Gasket Profile H 5 has the following special features:

Important: No sealing agents, such as solid lubricant paste, may be used with metal gaskets such as the H5 gasket.If these sealing agents are used they can cause indentations on the flange sealing surfaces, necessitating their repair before they can be reused.

Materials for the chambering ring:

1.4016,1.4541,1.4828,1.5415,1.7335

Materials for the sealing ring:

1.0035, 2.0090, 2.3040, 2.4066, 3.0255

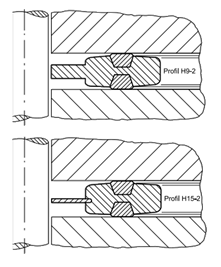

If the gasket is to be installed between two smooth flanges, we recommend Profile H9 with centring ring and/or H15 with loose metal centring ring.