Everything for maintenance e. g. Ringcutter

We have a large variety of maintenance products in stock

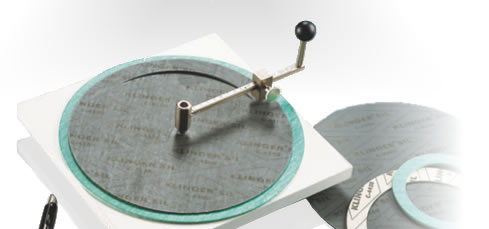

Ringcutter

Area Of Application:

For cutting seals on site and for quick service on the go and for mobile workshops.

The ring cutting machine was originally developed for cutting sealing plates without a metallic insert, e.g. KLINGERSIL® or KLINGER® Topchem products.

Basically, it is also possible to cut sealing plates like KLINGER® graphite laminate and KLINGER® Milam. The cutting result is also influenced by the manual skill of the respective user.

Features:

The machine is suitable for producing flat gaskets in the form of rings. It cuts almost all cutting sealing materials up to 9 mm depending on the type of material.

With handwheel

- Cutting range from 80 – 1250 mm

- Machine dimensions 1100x170x250 (LxWxH)

- Weight: 6.5kg

Standard scope of delivery

- cutting mat

- centering bolt

- blade

- cutting compass

With circle

- quick assembly

- Easy to use

- Cutting range of 25 – 300 mm

- Weight: 2.05kg