WaveGuard

Grooved gaskets taken to the next level

WaveGuard

Resilient, adaptable, and resource-efficient: A wave of improvements.

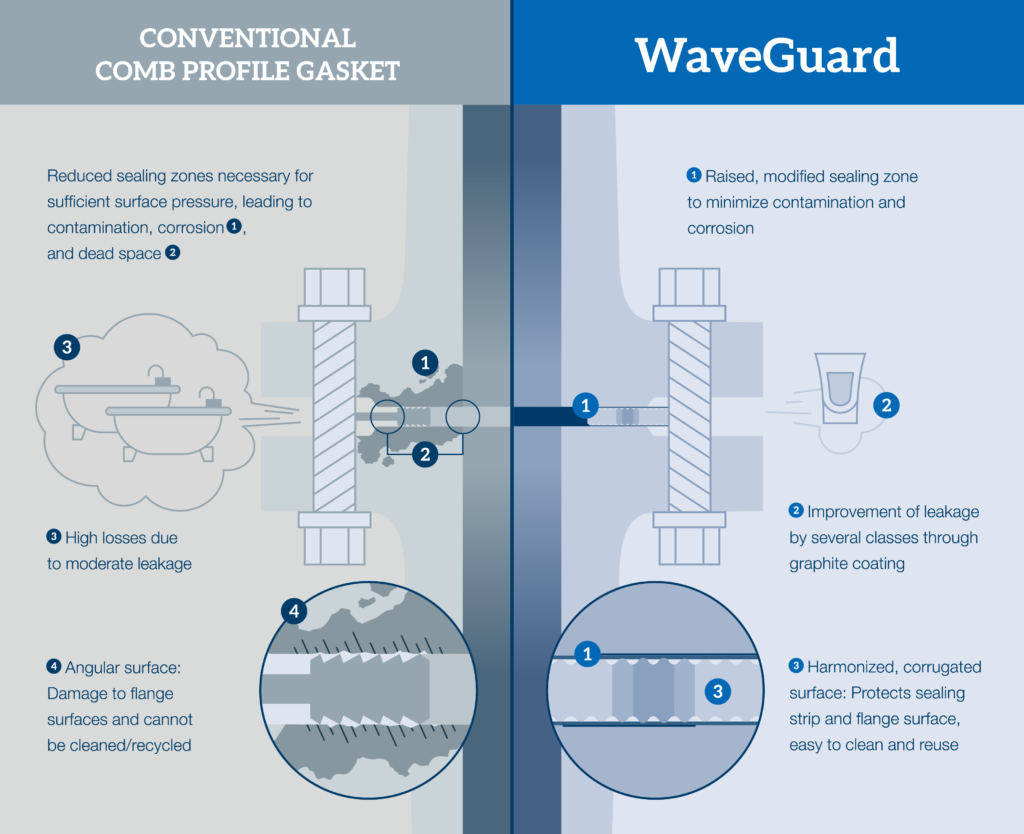

Grooved gaskets have proven themselves for good reason: With soft material overlays, a secure seal is achieved with low minimum surface pressure. At the same time, they are very resilient thanks to their metal core.

They can withstand high pressures and temperatures and are ideal for demanding operational safety requirements.

However, grooved gaskets also have significant disadvantages: Their comparatively high leakage values cause media losses, and they also cause contamination and – if the flange cover is insufficient – corrosion damage. The sharp-edged surface also has a negative effect: It makes reuse difficult and can damage the sensitive flange surface.

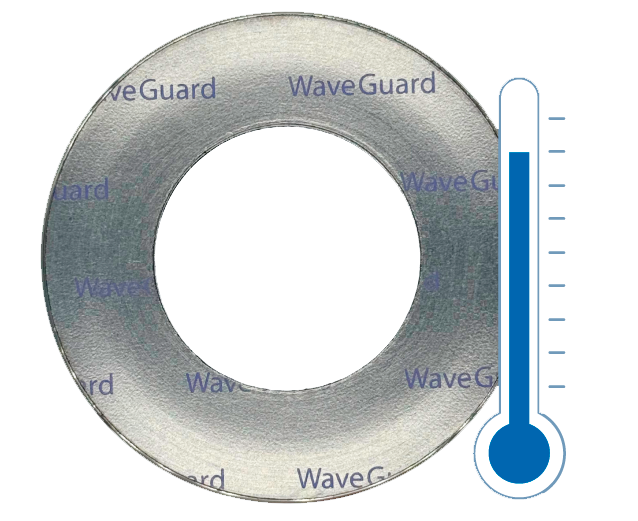

The WaveGuard gasket was developed with an innovative, wave-shaped geometry. It offers the proven advantages of classic grooved gaskets – high sealing performance and reliable function – while eliminating their typical weaknesses such as increased leakage, contamination, or damage to the flange surface.

DETAILED INFORMATION of waveguard

The WaveGuard seal is designed to be efficient and offer real added value.

The raised, modified sealing surface improves leakage, while the wave-like surface protects the flange and is easy to clean.

This results in a seal with a number of advantages:

- EXCELLENT LEAKAGE PERFORMANCE

- PROTECTED FLANGE

- VERSATILE

- SUSTAINABLE

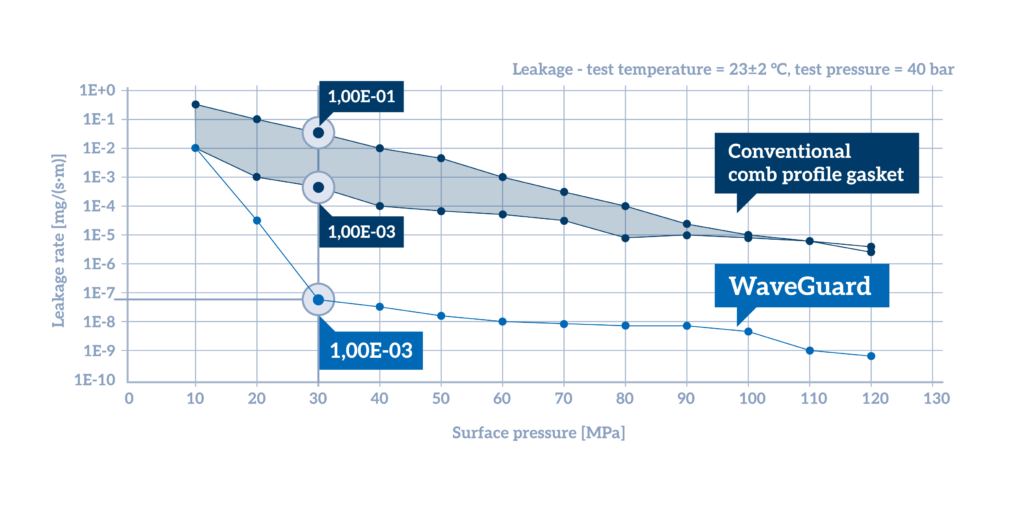

» EXCELLENT LEAKAGE PERFORMANCE

Improvement of up to 6 leakage classes at 30 MPa.

Further technical data can be found at www.esadata.org

» VERSATILE

Depending on the area of application, the covering layer can be selected accordingly, such as graphite, mica for high-temperature

environments above 500°C, or Egraflex Steelflon for residue-free removal.

» PROTECTED FLANGE

Centering is achieved via the outer diameter. Unlike conventional grooved gaskets which have an integrated centering and therefore more vulnerable centering edge, the WaveGuard is solid. This prevents the risk of fatigue fractures caused by vibration. Contamination and corrosion are reduced by the full-surface coverage.

» SUSTAINABLE

Emissions are reduced due to low leakage.

The seal can be easily cleaned, checked, and replaced if necessary, making it reusable.