Is the internal pressure sufficient?

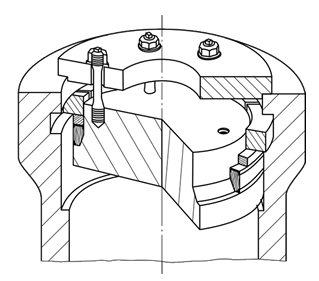

Cup seals are used as self-sealing gaskets, meaning that the sealing force does not come from bolts but from the internal pressure. Therefore bolts with a smaller cross section can be selected. The entire connection is more compact.

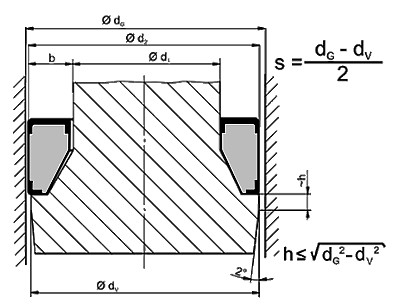

The following illustration shows the design principle.At high pressures or with reworked covers, caps should be provided, so that the graphite does not extrude into the gap between the housing and the cover plate. Compressed caps are made of 0.4 mm thick stainless steel sheet metal 1.4541.

At very high pressures solid, lathed capsare usual.

| Indicative values for maximum bridgeable gaps: | ||||||

|---|---|---|---|---|---|---|

b [mm] | 5 | 10 | 15 | 20 | 30 | 40 |

s [mm] | 0,4 | 0,6 | 0,8 | 1,0 | 1,2 | 1,3 |

Gap width s is the average gap as shown in the illustration

When new, the gap should be as narrow as possible. The specified fit tolerance can be used as an indicator. The selection and model is left to the equipment

diameter d₂ | tolerance zone dG/dV |

|---|---|

d₂ < 500mm | D9/h8 |

d₂ > 500mm | E8/h8 |

The cover plate can be tilted by 1° or 2° as shown in the illustration, for ease of fitting. Cover plate gaskets have a rectangular or an internally (less often, externally) sloped cross-section.

There is a range of profiles in seven different shapes available, with which all sealing problems can be solved. The necessary deformation to conform to the sealing surfaces is achieved with the cover tensioning bolts. When laying out the bolts, attention should also be paid to the weight of the cover and where it is to be installed. Depending on the type of profile and the geometry of the gasket, achieving sufficient deformation will require the correct level of surface pressure and/or the correct internal pressure.

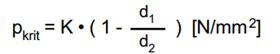

The minimum pressure required for a self-sealing connection is given as pkrit . Where d1 =internal diameter and d2 = external diameter of the gasket, and the sealing factor is K, the following is true:

| Construction and material of the gasket |  |  |  |  |  |  |  | RZ* [µm] |

| Graphite ring, Profile series P70 made from chemically pure graphite, "RivaTherm" | P71 | P71K | P71KL | P74 | P74K | P75 | P75K | 12,5 to 25 |

| Factor K (N/mm2 ) | 100 | 110 | 90 | 70 | 80 | 70 | 80 |

The maximum permitted operating or test pressure can also be estimated from the critical pressure. The selected tolerances and the presence or absence of metal caps or lathed protective caps is of critical importance.

The following gives an indication:

| Preasure | Ausführung |

| pmax > 3 x pkrit | Withoutcaps |

| 3 x pkrit < pmax< 6 x pkrit | Withmetalcaps |

| 6 x pkrit < pmax< 12 x pkrit | Withlathedsteelcap |