Shut off pipelines during pressure tests or maintenance work

OUR STANDARD

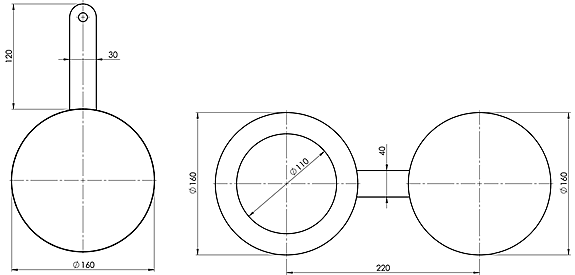

Line blinds and spectacle line blinds for shutting off pipelines during pressure tests or maintenance work. As standard, we use 1.4301 or 1.0425.

Other materials or pressure ratings are available on request at any time.

After placing a blind disc, the pipeline is often vented via balanced flange connections. This poses risks to people and the environment. When handling hazardous materials, appropriate openings and nozzles must be introduced into the pipeline. Depending on the pipe classification, these welded joints can be produced and tested with a greater or lesser effort.

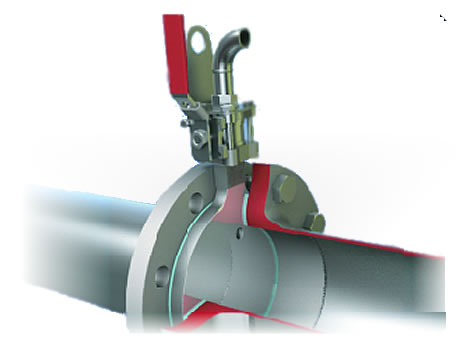

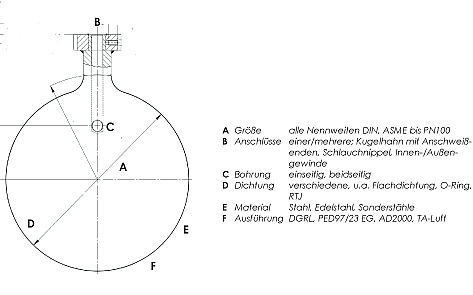

Our line blind has an integrated lockable bore and thus ensures safe and easy draining and venting of pipelines without drilling and welding. The intermediate clamp design allows problem-free handling.

The integrated bore with the external shut-off valve allows the pipeline to be specifically vented or emptied. Escaping medium can be discharged or collected without endangering the environment or employees.

Our line blinds are available for DIN and ASME flanges, made of different materials and with a large number of connection variants, as well as spectacle line blinds.

Different sealing systems can be considered. Versions according to DGRL, PED97/23 EG, AD-2000 or TA-Luft are possible.

The benefits of our line blinds are problem-free handling with hazardous media and simple installation without processing the pipeline.

The portable blind can be used flexibly in different places. Due to the wide range of material and connection options, the subject of draining and venting pipes can be handled for almost any medium.

Labour, health and safety policy issues can be resolved without compromise.

Are there any important process parameters missing to be successful in troubleshooting?

Are you looking for a quick and uncomplicated way to introduce a pressure measurement or a sampling point into a pipeline?

It is not possible to insert corresponding openings and nozzles into the pipeline because the welded connections have to be made and tested with more or less effort, depending on the pipe classification?

Do you want to reduce costs for the work on the pipelines?

Our line blinds are the right solution!