Lens seals are re-usable several times

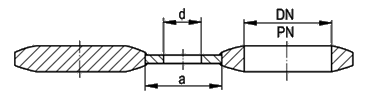

Lens seals are reusable, as the sealing effect is generally achieved by elastic deformation of the surfaces. The projected sealing width bG is calculated in relation to the angle a, which forms the sealing surface against the direction of the force (tubular axis) depending on the E modulus EG and the surface pressure exerted by bG = 100 • σ / EG • r • sinα.

Lens seals are impervious to overpressure. Within creasing loads, the contact surface between the sphericallens surface and thespherical flange groove increases, so that the surface pressure only increases to a lesser extent.

A disadvantage with standard sealing lenses is that, at high pressures and temperatures, the sealing lens can bulge along the circumference and weaken the tension of the connection. Also, at greater nominal diameter, the flange can become stuck in the area of the raised face diameter d5 and lift up at the sealing diameter.

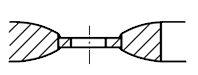

We can also specially produce bellows lenses, lens blind spectacle gaskets and half-lenses. Lens blind spectacle gaskets are made of a sealing lens and a lens blind, which are connected by a ligament. It is also usual to use lens blinds on their own. In this case, it is useful to weld on a small plate to render the lens blind distinguishable.

| Steel type designation | Materialnumber | for circulatory temperatures | Code designationon the outer edge |

|---|---|---|---|

| S235JRG2 | 1.0038 | to 425°C | none |

| P265GH | 1.0425 | to 425°C | none |

| 16Mo3 | 1.5415 | 425 to 475 | 1 Ankörnung |

| 13CrMo4-5 | 1.7335 | 425 to 520 | 2 Ankörnungen |

| 10CrMo9-10 | 1.7380 | 520 to 580 | 3 Ankörnungen |

| X6CrNiTi18-10 | 1.4541 | 350 to 550 | 4 Ankörnungen |

| 12CrMo19-5 | 1.7362 | Max 650°C | 1 Kerbe |

| X6CrNiMoTi17-12-2 | 1.4571 | Max 550°C | 3 Kerben |

| Profile | A5, A5S, A5BS | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Iron 1.100 Stw24modd | Heat-resistant mild steel 1.5415 | Heat-resistant mild steel 1.7362 | Stainless Steel 1.4541 | Stainless Steel 1.4828 | Steel ST 35 cooper-plated | Steel 1.4541 silver-plated | Cooper 2.0090 | Monel 2.4360 | ||

| Recommended max. roughness of the flange surfaces | µm | from to | 3,2 6,3 | 3,2 6,3 | 3,2 6,3 | 1,6 3,2 | 1,6 3,2 | 3,2 6,3 | 6,3 12,5 | 3,2 6,3 | 3,2 6,3 |

| Surface pressure limits for 20 °C | N/mm2 | σv σϑ | 235 525 | 300 675 | 400 900 | 335 750 | 400 900 | 135 600 | 100 750 | 135 300 | 260 660 |

| E modulus at 20 °C | kN/mm2 | 210 | 210 | 210 | 200 | 200 | 210 | 200 | 128 | 178 | |

| Surface pressure limits for 300 °C | N/mm | σv σϑ | 235 315 | 300 585 | 400 730 | 335 630 | 400 750 | 135 390 | 100 630 | 135 150 | 260 650 |

| E modulus at 300 °C | kN/mm2 | 185 | 185 | 190 | 186 | 186 | 185 | 186 | 114 | 175 | |