Suitable for gas and vacuum technology

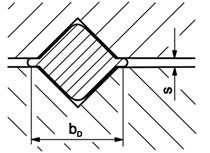

Round wire gaskets are used in gas and vacuum engineering. Standard materials used include soft-annealed aluminium, copper, silver and nickel. Lathed rings and rings bended and welded from calibrated wire can be supplied. Round wire gaskets are usually inserted in grooves. Some possible options are shown here.

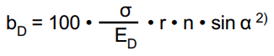

If the gaskets are generally elastically deformed, the sealing surface width arising should first be calculated using the following formula:

If the gaskets are generally elastically deformed, the sealing surface width arising should first be calculated using the following formula:

It should be noted that a small wire and/or sealing diameter will place higher demands on the groove and on the gasket with regard to size, tolerances and surface quality. Lathed rings should be used in this case. With welded models, strong plastic deformation is required. If the material displays full plasticity, such as aluminium, soft copper, silver or gold, the seal width bD is equal to the groove width b. Full plastic deformation requires much higher bolt loads than the more predominant elastic deformation.

It should be noted that a small wire and/or sealing diameter will place higher demands on the groove and on the gasket with regard to size, tolerances and surface quality. Lathed rings should be used in this case. With welded models, strong plastic deformation is required. If the material displays full plasticity, such as aluminium, soft copper, silver or gold, the seal width bD is equal to the groove width b. Full plastic deformation requires much higher bolt loads than the more predominant elastic deformation.

The cross-section surfaces for full plastic deformation should be dimensioned in such a way that the round ring can fill the groove cross-section in its deformed state. Generally a gap of a few tenths of a millimetre should be left.

1.0333, 3.0255, 2.0090, 2.4066, fine-grainsilver

| Materials | Iron 1.0333 | Aluminium 3.0255 | Cooper 2.0090 | Nickel 2.4066 | Fine-grainsilver | ||

|---|---|---|---|---|---|---|---|

| Recommended max. roughnessof the flange surfaces | µm | von bis | 3,2 6,3 | 3,2 6,3 | 3,2 6,3 | 3,2 6,3 | 3,2 6,3 |

| Surface pressurelimits for 20 °C | N/mm2 | σv σϑ | 265 600 | 70 140 | 135 300 | 190 510 | 100 190 |

| E modulus at 20 °C | kN/mm2 | 210 | 70 | 128 | 206 | 79 | |

| Surface pressurelimits for 300 °C | N/mm | σv σϑ | 265 390 | - - | 135 150 | 100 480 | 100 145 |

| E modulus at 300 °C | kN/mm2 | 185 | - | 114 | 118 | 70 | |